Here are the steps that a scanner goes through when it scans a document:

•The document is placed on the glass plate and the cover is closed. The inside of the cover in most scanners is flat white, although a few are black. The cover provides a uniform background that the scanner software can use as a reference point for determining the size of the document being scanned. Most flatbed scanners allow the cover to be removed for scanning a bulky object, such as a page in a thick book.

•A lamp is used to illuminate the document. The lamp in newer scanners is either a cold cathode fluorescent lamp (CCFL) or a xenon lamp, while older scanners may have a standard fluorescent lamp.

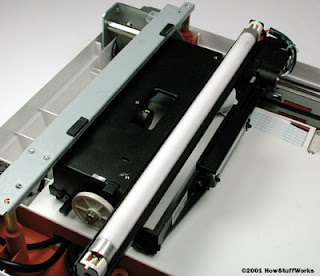

•A lamp is used to illuminate the document. The lamp in newer scanners is either a cold cathode fluorescent lamp (CCFL) or a xenon lamp, while older scanners may have a standard fluorescent lamp. •The entire mechanism (mirrors, lens, filter and CCD array) make up the scan head. The scan head is moved slowly across the document by a belt that is attached to a stepper motor. The scan head is attached to a stabilizer bar to ensure that there is no wobble or deviation in the pass. Pass means that the scan head has completed a single complete scan of the document.

•The image of the document is reflected by an angled mirror to another mirror. In some scanners, there are only two mirrors while others use a three mirror approach. Each mirror is slightly curved to focus the image it reflects onto a smaller surface.

•The image of the document is reflected by an angled mirror to another mirror. In some scanners, there are only two mirrors while others use a three mirror approach. Each mirror is slightly curved to focus the image it reflects onto a smaller surface. •The last mirror reflects the image onto a lens. The lens focuses the image through a filter on the CCD array.

The filter and lens arrangement vary based on the scanner. Some scanners use a three pass scanning method. Each pass uses a different color filter (red, green or blue) between the lens and CCD array. After the three passes are completed, the scanner software assembles the three filtered images into a single full-color image.

The filter and lens arrangement vary based on the scanner. Some scanners use a three pass scanning method. Each pass uses a different color filter (red, green or blue) between the lens and CCD array. After the three passes are completed, the scanner software assembles the three filtered images into a single full-color image. Most scanners today use the single pass method. The lens splits the image into three smaller versions of the original. Each smaller version passes through a color filter (either red, green or blue) onto a discrete section of the CCD array. The scanner combines the data from the three parts of the CCD array into a single full-color image.

Another imaging array technology that has become popular in inexpensive flatbed scanners is contact image sensor (CIS). CIS replaces the CCD array, mirrors, filters, lamp and lens with rows of red, green and blue light emitting diodes (LEDs). The image sensor mechanism, consisting of 300 to 600 sensors spanning the width of the scan area, is placed very close to the glass plate that the document rests upon. When the image is scanned, the LEDs combine to provide white light. The illuminated image is then captured by the row of sensors. CIS scanners are cheaper, lighter and thinner, but do not provide the same level of quality and resolution found in most CCD scanners.

Resolution and Interpolation

Scanners vary in resolution and sharpness. Most flatbed scanners have a true hardware resolution of at least 300x300 dots per inch (dpi). The scanner's dpi is determined by the number of sensors in a single row (x-direction sampling rate) of the CCD or CIS array by the precision of the stepper motor (y-direction sampling rate).

For example, if the resolution is 300x300 dpi and the scanner is capable of scanning a letter-sized document, then the CCD has 2,550 sensors arranged in each horizontal row. A single-pass scanner would have three of these rows for a total of 7,650 sensors. The stepper motor in our example is able to move in increments equal to 1/300ths of an inch. Likewise, a scanner with a resolution of 600x300 has a CCD array with 5,100 sensors in each horizontal row.

Sharpness depends mainly on the quality of the optics used to make the lens and the brightness of the light source. A bright xenon lamp and high-quality lens will create a much clearer, and therefore sharper, image than a standard fluorescent lamp and basic lens.

Of course, many scanners proclaim resolutions of 4,800x4,800 or even 9,600x9,600. To achieve a hardware resolution with a x-direction sampling rate of 9,600 would require a CCD array of 81,600 sensors. If you look at the specifications, these high resolutions are usually labeled software-enhanced, interpolated resolution or something similar. What does that mean?

Interpolation is a process that the scanning software uses to increase the perceived resolution of an image. It does this by creating extra pixels in between the ones actually scanned by the CCD array. These extra pixels are an average of the adjacent pixels. For example, if the hardware resolution is 300x300 and the interpolated resolution is 600x300, then the software is adding a pixel between every one scanned by a CCD sensor in each row.

Another term used when talking about scanners is bit depth, also called color depth. This simply refers to the number of colors that the scanner is capable of reproducing. Each pixel requires 24 bits to create standard true color and virtually all scanners on the market support this. Many of them offer bit depths of 30 or 36 bits. They still only output in 24-bit color, but perform internal processing to select the best possible choice out of the colors available in the increased palette. There are many opinions about whether there is a noticeable difference in quality between 24-, 30- and 36-bit scanners.

Image Transfer

Scanning the document is only one part of the process. For the scanned image to be useful, it must be transferred to your computer. There are three common connections used by scanners:

•Parallel - Connecting through the parallel port is the slowest transfer method available.

•Small Computer System Interface (SCSI) - SCSI requires a special SCSI connection. Most SCSI scanners include a dedicated SCSI card to insert into your computer and connect the scanner to, but you can use a standard SCSI controller instead.

•Universal Serial Bus (USB) - USB scanners combine good speed, ease of use and affordability in a single package.

•FireWire - Usually found on higher-end scanners,FireWire connections are faster than USB and SCSI. FireWire is ideal for scanning high-resolution images.

On your computer, you need software, called a driver, that knows how to communicate with the scanner. Most scanners speak a common language, TWAIN. The TWAIN driver acts as an interpreter between any application that supports the TWAIN standard and the scanner. This means that the application does not need to know the specific details of the scanner in order to access it directly. For example, you can choose to acquire an image from the scanner from within Adobe Photoshop because Photoshop supports the TWAIN standard.

On your computer, you need software, called a driver, that knows how to communicate with the scanner. Most scanners speak a common language, TWAIN. The TWAIN driver acts as an interpreter between any application that supports the TWAIN standard and the scanner. This means that the application does not need to know the specific details of the scanner in order to access it directly. For example, you can choose to acquire an image from the scanner from within Adobe Photoshop because Photoshop supports the TWAIN standard. In addition to the driver, most scanners come with other software. Typically, a scanning utility and some type of image editing application are included. A lot of scanners include OCR software. OCR allows you to scan in words from a document and convert them into computer-based text. It uses an averaging process to determine what the shape of a character is and match it to the correct letter or number.

The great thing about scanner technology today is that you can get exactly what you need. You can find a decent scanner with good software for less than $200, or get a fantastic scanner with incredible software for less than $1,000. It all depends on your needs and budget.

***THE END

*article from howstuffworks.com

No comments:

Post a Comment